Titanium is a corrosion-resistant metal. It reacts with oxygen to form a stable and dense oxide film, which is stable in oxidizing medium, neutral medium or weak reducing medium. Therefore, industrial pure titanium can be directly used in many media, or suitable corrosion inhibitors can be added into the media, but titanium generally does not have corrosion resistance in reducing acid solution. Adding PD into titanium can improve the performance of reducing acid corrosion resistance of titanium and crevice corrosion resistance of titanium.

Gr.7(TA9) titanium rod (Ti Pd alloy) has excellent corrosion resistance in oxidizing medium. It also has certain corrosion resistance to reducing medium, especially to improve its crevice corrosion resistance in high chloride concentration medium. Ta9 titanium rod contains 0.2% palladium. In 5% boiling sulfuric acid, the corrosion rate of ta9 titanium palladium alloy can be reduced from 48.26mm/a (industrial pure titanium) to 0.508mm/a, and the corrosion resistance can be increased by 95 times. The alloy has good processing, forming and welding properties, but it contains precious metal palladium and has high cost.

Corrosion resistant titanium alloy is suitable for application in strong corrosive medium, mainly low strength alloy. In the field of non aerospace, the advantage of good corrosion resistance is mainly used. Corrosion resistant titanium alloys improve the corrosion resistance of industrial pure titanium in reducing media (such as hydrochloric acid, sulfuric acid, phosphoric acid, oxalic acid and formic acid). At present, the mature titanium molybdenum, titanium palladium, titanium molybdenum nickel, titanium nickel, titanium tantalum and other alloys.

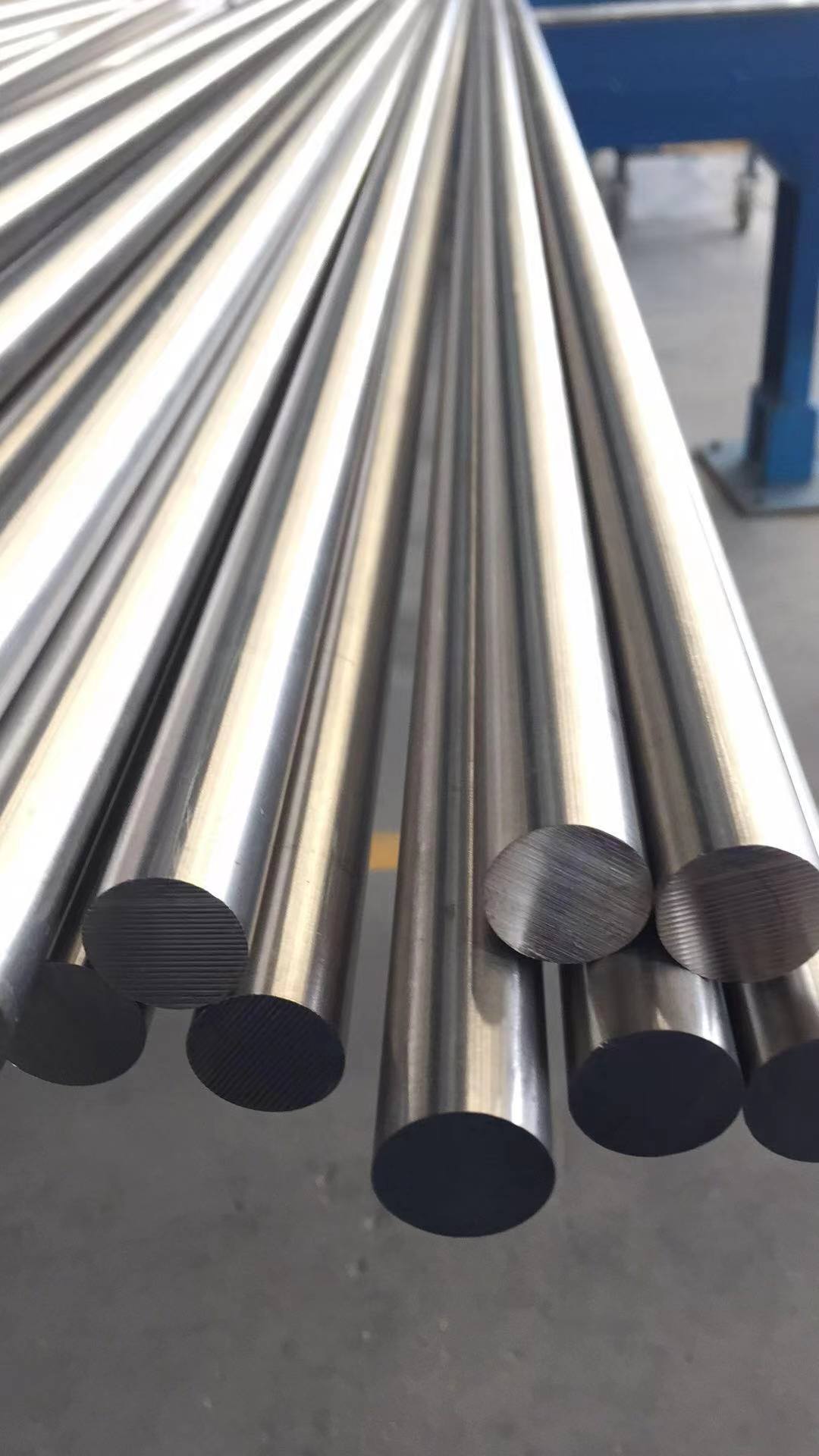

Gr.7(TA9) titanium rod (titanium palladium alloy)

Ti PD alloys include ti-0.2pd, Ti-0.15pd and Ti-0.13pd. Among them, Ti-0.2pd is widely used in reactors, towers, autoclaves, heat exchangers, pumps, valves, centrifuges, separators, pipes, pipe fittings and electrolyzers in various corrosive environments.

Grade chemical composition Ti PD Fe N C H O

Gr.16(TA8) Ti-0.05pd margin 0.04-0.08 < 0.30 < 0.03 < 0.08 < 0.015 < 0.25

Gr.17(TA8-1) Ti-0.05pd residual 0.04-0.08 < 0.20 < 0.03 < 0.08 < 0.015 < 0.18

Gr.7(TA9) Ti-0.20pd residual 0.12-0.25 < 0.30 < 0.03 < 0.08 < 0.015 < 0.25

Gr.11(TA9-1) Ti-0.20pd residual 0.12-0.25 < 0.20 < 0.03 < 0.08 < 0.015 < 0.018

Mechanical property

Tensile strength: > 370mpa; yield strength: > 250Mpa; elongation after fracture: > 20%; reduction of area: > 25%

Gr.12(TA10) titanium rod (Ti Mo Ni alloy)

The nominal composition of TA10 titanium rod (Ti Mo Ni alloy) is ti-0.3mo-0.8ni. It is a ti-12 alloy researched and developed by the United States in the mid-1970s. It is a kind of anti crevice corrosion titanium alloy. The tensile strength of the alloy at 300 is twice as high as that of pure titanium. The corrosion resistance of the alloy in reducing medium is obviously improved. Crevice corrosion does not occur in 150-200 chlorides.